Happy New Year!

So, 2018 was the year I moved and 2019 was the year I finally went to Paris (!!!) and both years were overflowing with crazy work hours. In this week before 2020 begins I’m working on ways to make more time to sew and renewing my commitment to blogging. Here’s hoping I can turn intention into reality.

Of course, Paris was absolutely magical. How could it not be? I tried keeping a journal, which only lasted two days. I started drafting a blog post about the trip. That didn’t get very far. I’m finding that I can’t seem to do the experience justice with mere words. There is, quite literally, nothing I can say about it that hasn’t been said so much better by the most extraordinarily talented people who have ever lived. Who am I to think I have anything to add to that?

Of course, there are some tangible things I brought home from Paris, primarily fabric. (As if that’s surprising!) The extraordinary fabric you see here is from Tissus Edré. It went (almost) directly from my suitcase to my cutting table. It was the first thing that caught my eye when I arrived with Susan Khalje’s Paris Tour group, and my BFF Stephanie from 10sewingmachines.blogspot.com had to remind me about it when it was time to check out because my head was filled with so many other treasures that surrounded us.

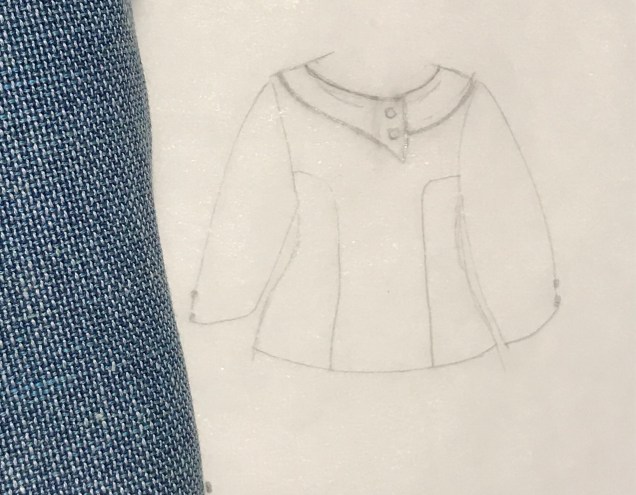

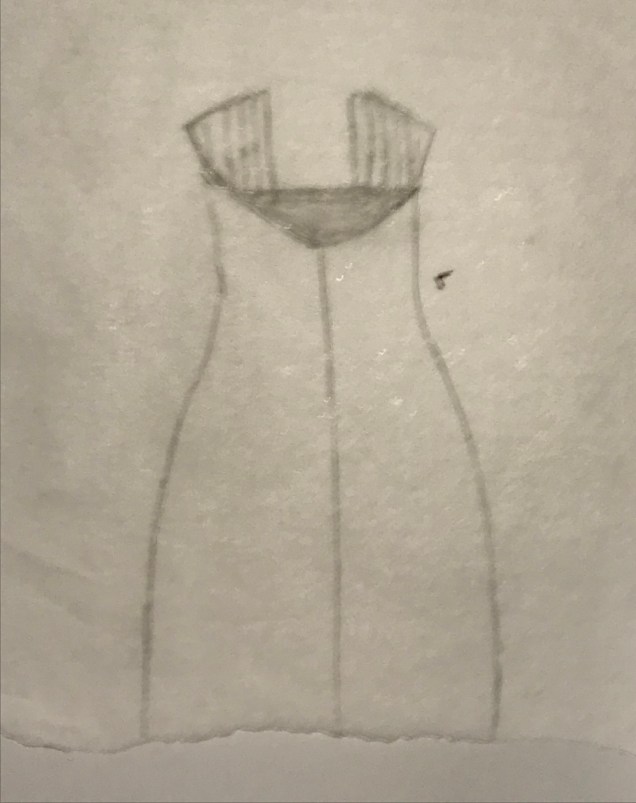

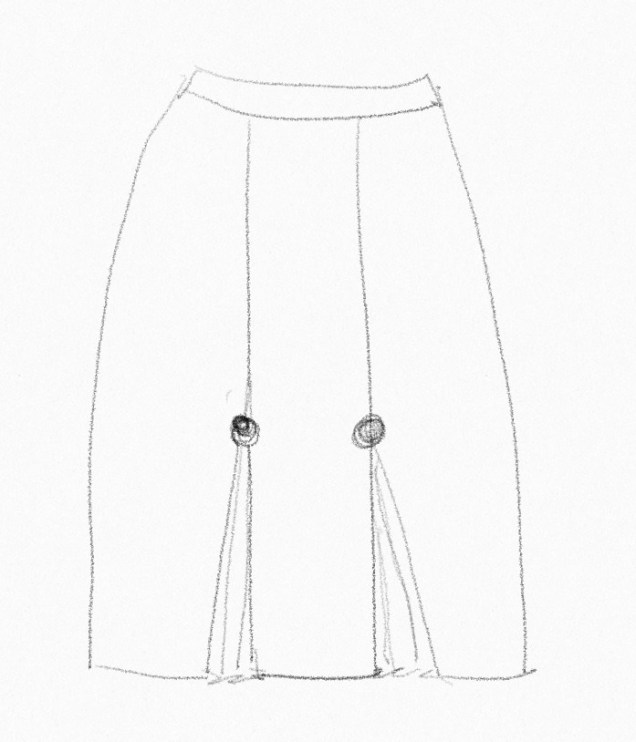

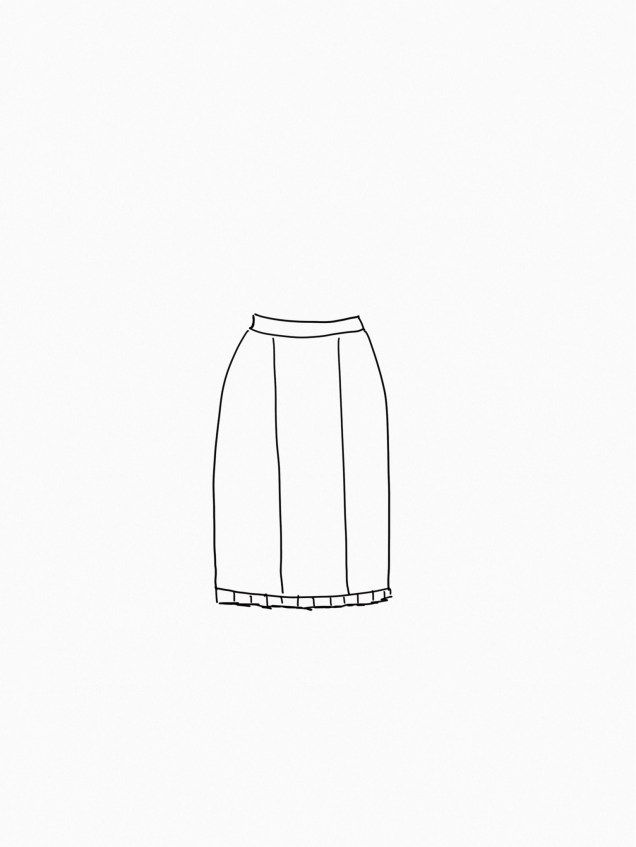

I bought three meters, plenty for a dress, but then decided what I wanted to do was make a top and use the rest for a bodice on a cocktail dress at some unspecified point in the future. When I started the project I planned to wear it with a black wool skirt to a holiday luncheon and later make a skirt in black silk to go with it. I never made it to the luncheon because I succumbed to a nasty bug that was going around. By then I realized that what this top really needs is a pair of black silk evening pants with pleats going all the way down the front that move like a long skirt when I walk. Steph and I are seeing Madame Butterfly at the end of February. It’s the last opera in our subscription for this season and it’s on a Saturday night, so this will be perfect to wear then. I wish I had the ability to convey this particular design in a sketch, but that’s beyond my capabilities.

This fabric is an interesting combination of green silk (which looks more like teal in some pictures), gold thread and black netting that connects everything. The netting isn’t only functional. It is thicker than what you find in most lace – almost the consistency of what you would use for cording. And it has variations in the pattern used in different places, with some areas more dense than others.

At first I thought I wanted to use a lining or underlining that matches my skin tone. But in testing I changed my mind. I think using a black underlining makes the green more vibrant.

The fabric was surprisingly easy to work with. To avoid adding excessive weight, I chose China silk for the underlining.

For seam finishes, I made some tests on the serger, using Polyarn from Superior Threads in the loopers to keep it soft. I tried using a narrow hem, but found that was too dense and ended up using a 3-thread overlock with a narrow width and fairly short stitch length.

I thought about using a hand rolled narrow hem, but with the underlining a regular hem by hand worked great. For the neckline finish, I made a narrow facing out of silk organza cut on the bias that I steamed to the shape of the patter pieces, then trimmed to size and stitched together at the shoulders. Once it was sewn in place, pressed and understitched, I sewed the bottom edge to the underlining by hand.

Here I am trying on the finished garment. I just threw it on and didn’t realize I hadn’t gotten it straight before taking the picture. I’ll take a better picture when I have the complete ensemble.